Camaro Performance Suspension:

The Camaro was designed to have a performance suspension for high G-force handling from a stock sport vehicle but there are many upgrades available if you want better cornering or off the line traction. Improvements to the stock suspension can be targeted to road racing or drag racing. Drag racing optimized suspensions tune the weight transfer to the rear wheels for improved traction while road race suspensions are optimized for lateral cornering and balanced fore-aft braking and acceleration loading.Road race course handling performance is improved by keeping the load of the vehicle on all four tires equally. Body roll tends to transfer weight to the outer tires reducing the contribution of the tires on the inside of the turn. During the eighties the debate was waged between the handling improvements contributed by sway bars vs spring rates. Both are essential but Herb Adams was perhaps the strongest proponent of the LARGE sway bar to control roll rates to improve handling. Cars destined for the smooth asphalt race track can accommodate lowered stiff springs to lower "Center of gravity" (CG) and reduce body roll but this suspension philosophy fails when introduced to pot holes, road crowns and the natural undulations of the public roads. Cars destined for the street need softer spring rates not just for a smoother ride, but also to keep the tires in contact with the road. To make up for the softer street springs, stiff roll bars are recommended.

Performance polyurethane bushings are often used to replace the stock rubber bushings. The intent is to limit adverse geometry changes due to heavy load resulting from aggressive driving and hard cornering. Front suspension deflections will change the desired caster and camber settings to that less optimal for cornering, thus decreasing cornering performance. Bushings made from solid aluminum or steel or use of heim joints will eliminate unwanted movement of suspension components but will also transmit tremendous forces directly to the chassis. Polyurethane components will provide improved stability while affording some cushioning. Bump stops made of Polyurethane are also superior to the stock item as they absorb more of the bump with less rebound.

Suspension Components:

Suspension vendors and components to improve race performance:

| PST: Performance Suspension Technology PST Part #: FEKPGCHE821

|

This is a performance front-end components rebuild kit for the 1982-92 Camaro with "Polygraphite" bushings to improve vehicle control and responsiveness. Kits also available for 1967-81 and 1993-2002 Camaros. |

| Hawks Third Gen

Available in red or black |

Polyurethane rear bump stops and machined aluminum spacers.

Polyurethane rear bump stop installed. This limits axle travel and reduces rebound forces. |

Energy Suspension

|

Gen one Camaro sub-frames shown with Energy Suspension front-end components. |

Herb Adams suspensionMoroso Part #:

|

This forged and heat treated chrome-moly steel sway bar is substantially thicker than the stock Z28 sway bar. |

KoniPart #:

|

Front shock replacement, Koni three way gas shock.

|

| Front upper strut mount (also known as "Camber Plates") |

After market front upper strut mount is stiffer and may offer greater range of adjustment. |

| QA1:

Third gen strut and camber plate. |

QA1 has both stock replacement strut/shocks and larger stronger units which require the QA1 Caster/Camber plate. Strut:

|

| QA1:

Third gen coil over rear shock. |

|

|

Front K-member:

See: |

Camaro/Firebird 82-92 LS1 / LS2 / LS6 / LS7 Conversion Appleton rack and pinion and K-Member Camaro/Firebird 82-92 LS1 / LS2 / LS6 / LS7 Conversion Appleton rack and pinion and K-MemberAlso see: |

| Heidts:

Third gen front and rear independent suspension kits. |

|

|

Heidts Third gen rear Ford 9" diff IRS kit |

|

Camaro Adjustable Suspension Installation:

An adjustable suspension allows one to adjust ride height, weight transfer control, stiffness and the corner weights to balance and tune the car's suspension. The front cross member replacement will help you lose a lot of weight from the front-end.Use the following components:

- Front:

- K-Member:

Spohn: F-Body LS Conversion K-Member

Spohn: F-Body LS Conversion K-Member

PA Racing: Beefy road racing K-Member

PA Racing: Beefy road racing K-Member

305 Schepman Ave, Seymour, IN 47274 (877)550-8400 Use Santhuff or Afco spring/shock combo and PA Racing rack and pinion kit. Regular unit uses 0.083 DOM tubing. Beefy unit uses 0.120" DOM tubing. F-Body Motorsport: LS1 Conversion K-member - front tubular K-member. Stock or rack and pinion steering, stock or coil-over front springs.

F-Body Motorsport: LS1 Conversion K-member - front tubular K-member. Stock or rack and pinion steering, stock or coil-over front springs.

BMR Fabrication: Tubular K-member - only 24 lbs! Save over 30 lbs over stock.

BMR Fabrication: Tubular K-member - only 24 lbs! Save over 30 lbs over stock.

Hawk/Spohn: 82-92 LS1 engine conversion K-Member - Uses Appleton 10:1 power rack and pinion kit, with spring perches(stock) or without (use coil over).

(LS1)

Hawk/Spohn: 82-92 LS1 engine conversion K-Member - Uses Appleton 10:1 power rack and pinion kit, with spring perches(stock) or without (use coil over).

(LS1)

201 Noble Rd., Easley SC 29640 (864)855-2694 AJE: Anthony Jones Engineering - Tubular front K-member (light weight) Optional spring perches. Pinto rack and pinion. It's a great weight reduction option for drag racing. Not sure of the flex control and durability for road use. Suggest contacting the manufacturer.

AJE: Anthony Jones Engineering - Tubular front K-member (light weight) Optional spring perches. Pinto rack and pinion. It's a great weight reduction option for drag racing. Not sure of the flex control and durability for road use. Suggest contacting the manufacturer.

6235 N. County Rd. 275 West, N. Vernon IN 47265 (800)877-7233

Art Morrison

Art Morrison

5301 8th St. East, Fife WA 98424 (800)929-7188- Tubular front lower control arms

- Upper spring mounting plate

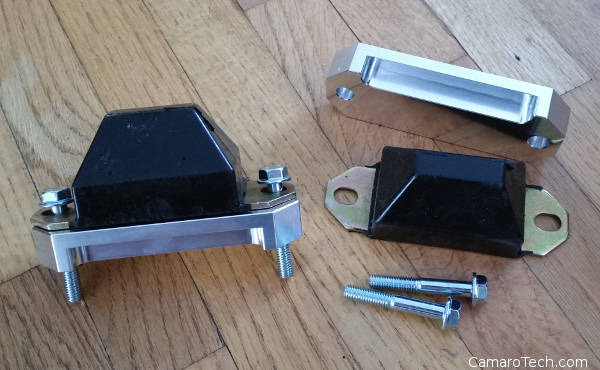

Moroso PN 62630 lower solid motor mount

Moroso PN 62630 lower solid motor mount

Koni Koni SPA-1 adjustable coil over strut with a 3 inch diameter coil spring.

Koni Koni SPA-1 adjustable coil over strut with a 3 inch diameter coil spring.

- K-Member:

- Rear:

Autofab - Third gen Camaro rear adjustable coil over kit with adjustable QA1 shock (Shock: DR5855B, spring: PN12-130) and Autofab bolt in brackets

Autofab - Third gen Camaro rear adjustable coil over kit with adjustable QA1 shock (Shock: DR5855B, spring: PN12-130) and Autofab bolt in brackets

7443 Washington Blvd., Elkridge MD 21075 (410)796-8777 QA1 Precision products - Rear shock PN DR5855B and spring: PN12-130

QA1 Precision products - Rear shock PN DR5855B and spring: PN12-130

21730 Hanover Ave, Lakeville MN 55044 (800)721-7761

Front Alignment:

-

First Gen

1967 - 1969Second Gen

1970 - 1981Third Gen

1982 - 1992Factory Performance Factory Performance Factory Performance Camber +1/4 degree +2 degrees +1 deg (+/-0.5deg) Caster +1/2 degree -1/2 to -3/4 degrees +3 deg (+/-0.5deg) Toe-In 1/8 inch 3/32 inch +0.15 deg (+/-0.05deg) +0.2 deg (+/-0.05deg)

Torque Specs:

-

Gen 3 Camaro:

Fastener Ft-Lbs N-m Strut to steering knuckle bolt 195 265 Strut upper mounting nut 50 70 Front upper strut mount to wheel housing tower 28 20 Front lower control pivot bolt nut 65 90 Bump stop to control arm 20 28 Control arm ball joint to steering knuckle 90 120 Steering knuckle to tie rod end nut 40 54 Tie rod clamp nut 14 19 Pitman arm to steering gear nut 180 250 Idler arm to frame nut 50 70 Power steering box to frame bolts 80 110

Shock Absorbers:

Features:- Custom Mount vs Stock Mount: Maintaining the stock mounting positions allows maintainability by any garage and replaceability by any OEM style replacement part. This may desirable for your street machine but ultimate performance may be had with a custom setup.

- Coil Over: Coil over assemblies allow for ride height adjustment and pre-compression adjustment to customize the spring stiffness. This is important in adjusting corner weights (see below). This is important for road course racers.

- Adjustable: Stiffness and rebound adjustment can adjust the ride for different applications such as drag racing, road courses and street driving. Drag racers prefer a shock setting on the front to allow extension to assist in weight transfer to the rear wheels. Road course racers prefer a stiff setting to improve handling. If on a date you might want to soften the ride for comfort.

- Material (steel/aluminum): Lighter is better. A lower un-sprung weight improves handling on bumps. The sprung weight is the vehicle which rides on the suspension. The un-sprung weight is the tire, wheel, control arms, spindle, brakes and shocks. It is always desired to have a low inertia assembly which can follow the contour of the bumps.

Terms:

Engineering terms:- DOM: Drawn Over Mandrel tubing results in uniform wall thickness and OD/ID concentricity. Cold drawn after forming results in higher yield and tensile strength than a tube with a welded seam.

- Geometric center line: The connecting line between the theoretical midpoints of the front spindles and the theoretical midpoints of the rear axle.

- Thrust line: Determined by bisecting the rear total toe angles where the toe angles are parallel to the tire/wheel assembly. A thrust line to the vehicle left is considered "Negative" and to the right is considered "Positive".

- Thrust Angle: is the angle created between the geometric center-line and the thrust line.

- Camber: The inward ("Negative") tilt or outward ("Positive") tilt at the top of the wheel assembly from the true vertical. Straight up and down is zero degrees camber.

- Toe: Toe-in ("Positive") is a condition where the front of the wheels are closer together that in the rear. Toe-out is considered "Negative". The amount of toe can be expressed in degrees or fractions of inches.

- Setback: If a vehicle has "rear setback" then one wheel assembly is further back from that on the opposite side of the vehicle.

- Caster: Forward ("Negative") or rearward ("Positive") tilt of the steering axis from true vertical. Caster is viewed from the side of the vehicle looking inward to the center of the vehicle. Positive caster gives the vehicle directional stability.

- SAI: (Steering Axis Inclination) The angle between the center-line of the steering axis and the vertical line from the center contact area of the tire (as viewed from the front). The effect of SAI is to urge the wheels to move to a straight ahead position after a turn. Inclining the steering axis inward causes the spindle to rise and fall as the wheel is turned one direction or the other. Increases the vehicle stability.

- IA: Included Angle = SAI + Camber

Spring Rate Calculations:

The spring rate as measured at the wheel is the stiffness as measured in pounds of force required for an inch of displacement.

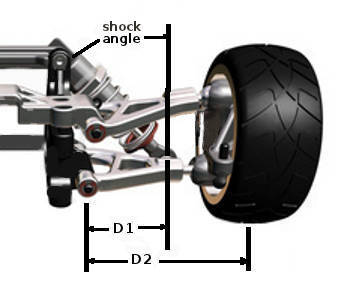

Due to the geometry of the suspension, the spring rate of the suspension spring may be very different than the spring rate at the wheel due to angles and lever arm lengths of the various components.

For any given suspension stiffness at the wheel, calculations are required to find the stiffness of the suspension spring.

The spring rate as measured at the wheel is the stiffness as measured in pounds of force required for an inch of displacement.

Due to the geometry of the suspension, the spring rate of the suspension spring may be very different than the spring rate at the wheel due to angles and lever arm lengths of the various components.

For any given suspension stiffness at the wheel, calculations are required to find the stiffness of the suspension spring.

Spring Rate Calculation:

Start with the weight of the car that all the springs will be supporting: W(car)

Calculate the weight that will be supported at each wheel: W = W(car)/4

The spring force of the suspension spring will be: (W * D2)/D1

Apply the spring rate correction factor below.

The actual spring rate is chosen by compressing (pre-loading) the spring to achieve the spring force required. A stiffer spring requires less pre-loading to support the weight and will provide a stiffer ride.

-

Example: desired spring rate = 250lbs-in mounted at 25 degrees.Shock Angle

(degrees)Correction Factor 0 1.00 10 0.96 15 0.93 20 0.88 25 0.82 30 0.75 35 0.66 40 0.59 45 0.50

Spring rate of 250lbs-in / 0.82 = 301 lbs-in required to provide the equivalent mounted rate.

The wheel rates are often adjusted for weight transfer and balance. For more on the adjustment of corner weights for vehicle balance see our article on measuring and suspension tuning of the vehicle corner weights.

Suspension geometry software for front and rear calculation of rebound movement, roll center, moment arm length, bump steer, ackerman geometry, roll steer, spring and shock travel, etc

Suspension Design Software

Online suspension geometry calculator

Links:

Manufacturer Links:

Spohn:

Spohn:

BMR Fabrication - control arms, Panhard rods, Panhard rod relocation kit, sway bars, Torque Arm

BMR Fabrication - control arms, Panhard rods, Panhard rod relocation kit, sway bars, Torque Arm

- QA1 - trailing arms, braces, strut tower braces, torque arms, panhard rods, sub frame connectors, tie rod sleeves

Global West Suspension: (67-02 Camaro components)

Global West Suspension: (67-02 Camaro components)

655 S. Lincoln Ave., San Bernardino CA 92408- Granatelli Motorsports - 3rd, 4th and 5th gen Camaro suspension components, subframes, braces and assemblies.

- Addco - sway bars

- Hellwig - sway bars

- Ingalls - specialized components to tweak your suspension adjustments. Camber/caster kits, offset bushings, offset bolts, shims, bushings, etc. Suspension tools. Lowered vehicle compensation.

- H-O Racing - 1st and 2nd gen Camaro F-Body suspension components

- Speed Tech: 1967 - 1981 Camaro A-arms

PA (Performance Automotive) Racing - Suspension components, rear panhard rod, control arms, K members, ...

PA (Performance Automotive) Racing - Suspension components, rear panhard rod, control arms, K members, ...

- Lower A-Arms

- Coil over suspension kit

- K (cross) Member kit Beefy road racing versions available.

Eibach - Performance suspension springs and suspension components.

Eibach - Performance suspension springs and suspension components.

Energy Suspension - Polyurethane components

Energy Suspension - Polyurethane components

PST: Performance Suspension Technology - Polygraphite components, sway bars, springs, suspension components.

PST: Performance Suspension Technology - Polygraphite components, sway bars, springs, suspension components.

Ingalls Engineering - Performance suspension components. Camber/caster offset bolts and bushings, suspension tools and components.

Ingalls Engineering - Performance suspension components. Camber/caster offset bolts and bushings, suspension tools and components.

34 Boston Court, Longmont CO 80501 (303)651-1297 (800)641-9795 Performance Suspension: Billet aluminum control arms for 3rd gen.

Performance Suspension: Billet aluminum control arms for 3rd gen.

(Tubular control arms, sway bars, brake kits, coil springs, spindles for 1st gen (1967-1969), 2nd gen (1970-1981) only.)- SSM: (Southside Machine) Traction bars (Drag racing)

259 E. Main Street, Smithville Ohio 44677 (216)669-3556 - Prothane: polyurethane mounts, isolators and bushings.

- Super Pro: performance suspension bushings and mounts. Fifth Gen Camaro.

- Mr Gasket: Lakewood Industries: Panhard rods, traction bars and dampers, sub-frame connectors, strut tower braces, etc

- Vette Brakes and Products - Camaro 1st and 2nd gen rear composite mono-spring (light)

- Whiteline - sway bars, bushings, control arms and link assemblies. Gen 5.

- Shock Absorbers:

- AFCO Racing - 5th gen Camaro

Koni Shock Absorbers - Koni - North America

Koni Shock Absorbers - Koni - North America

Bilstein Shock Absorbers

Bilstein Shock Absorbers

KYB - gas shocks

KYB - gas shocks

QA1 - performance and custom shock kits, components and tech info

QA1 - performance and custom shock kits, components and tech info

- Air Ride Technologies - Air suspension systems.

- Air Lift Company - Air suspensions systems.

- PRO Shocks

- Camber plates:

- Subframes:

- Art Morrison: 1st, 2nd and 3rd gen Camaro front suspension clips, also electric jack stands, roll cages, etc

- Chassis Engineering

- Moroso: Competition Engineering: sub-frames and chassis building components

- Jim Meyer Racing: racing and hot rod sub-frame suspension systems - 1st and 2nd gen Camaros

- S & W Race Cars